Five great achievements in the world of 3D printing

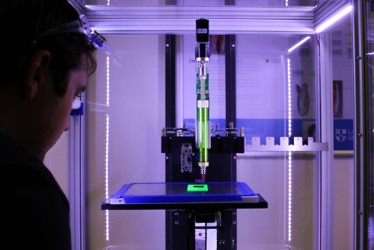

3D printing (additive or additive manufacturing) turns digital files into three-dimensional objects by stacking layers of material in a process known as additive manufacturing. The print heads release material in precise orientations that can create complex designs, from jewelry to three-story buildings. Some relevant data related to this technology are explained below.

3D printing

250 Materials: Modern 3D printers can produce full-color, functional objects from over 250 different materials, including metals, plastics, ceramics, glass, rubber, leather, stem cells, and even chocolate and other products.

100 times faster. Recently, innovative methods of stereolithography have made it possible to create complex shapes at a speed 100 times faster than traditional 3D printers. Starting with a layer of photoreactive liquid resin, it was found that the application of different wavelengths of light selectively hardens the resin as it is released, thus achieving continuous printing and eliminating gradual layering.

90% material efficiency: In addition to fast, high-resolution manufacturing, additive manufacturing has promising economic and environmental benefits, eliminating huge amounts of waste as raw material requirements are reduced by up to 90%.

3D printing opens up many possibilities for mass customization, democratization of production and systematic improvement. Major international advances in additive manufacturing are already accelerating these trends and creating new convergent programs. However, we have told more about how a 3D printer works on this web page.

5 innovations of 3D printing

The next 5 printing developments that will happen between 2019 and 2024 are:

1) The speed of 3D printing will increase by 50-100 times

The speed of 3D printing is usually limited by the force the print head can apply, how fast the printer can heat the material to cause flow, or how fast the print head itself can move. .

However, MIT's Manufacturing and Productivity Laboratory recently created a printer that is 10 times faster than traditional desktop models and 3 times faster than a $100,000 industrial system. In record speed, the MIT team printed a helical bevel gear in just 10 minutes and a pair of bezels in just 3.6 minutes. The acceleration of 3D printing will revolutionize almost every sector, from retail to manufacturing.

2) 3D-printed sustainable and affordable neighborhoods are being built

The construction and real estate industries are experiencing massive disruption as 3D printed homes offer cheaper and greener alternatives to traditional housing. 3D-printed houses first appeared last year in the Dutch city of Eindhoven, where a shortage of bricklayers has increased demand for the technology.

Futuristic buildings use less cement, which means less costs and less resources. In the future, home printers will include infrastructure, including drainage pipes and even potentially smart sensors, providing a fully integrated experience. As an example of this, recently a new company called NewStory was able to build 100 houses in 8 months for about $6,000 each. You can find out everything related to cryptocurrency here.

3) Delicious 3D printed steaks and burgers in restaurants

3D-printed meat using plant proteins will provide a more sustainable solution to feeding the world's growing population. Livestock production accounts for 14.5% to 18% of global anthropogenic greenhouse gas emissions. However, 3D-printed meat can satisfy consumers in the same way as traditional meat without the harmful impact on the environment. In the next five years, printing costs for these types of food will decrease and textures will improve. The Israeli company Chef-it and Giuseppe Scionti's NovaMeat have already succeeded in this.

4) Metal 3D printers will outperform plastic.

Metal 3D printers will not only eliminate waste in production, but also allow for lighter parts, which is a particularly important development for aircraft construction. In addition, 3D-printed jewelry, car and airplane parts, kitchenware, and prototypes can be made.

This technology will become increasingly available at the consumer level, providing more flexibility in product design than traditional plastic printers.

5) "Gay" will be the most used command in design development

"Hey Cogni, design a new pair of shoes, size 38, adapted to my weight," is a phrase we'll probably be using in the next five years. Smart 3D printers with natural language processing, generative design based on artificial intelligence and customization capabilities will ensure seamless design.